Pos:

Home KnowledgeTechnologyDiamond Wafer: Innovative Materials Leading Thermal Management in Electronic DevicesIn the rapidly changing field of electronic technology, the past 20 years have witnessed an astonishing reduction in device feature sizes, spanning from the micrometer level to the nanometer level, greatly driving the improvement of computing power. However, this progress is accompanied by a significant increase in power consumption, which poses new requirements for the cooling design of electronic devices, chips, and even the entire system architecture. The power output of high-performance computing modules has reached 200-250W, while the total thermal load of processors in a four slot computing system approaches 1 kW, which poses a severe challenge to the thermal management of electronic devices.

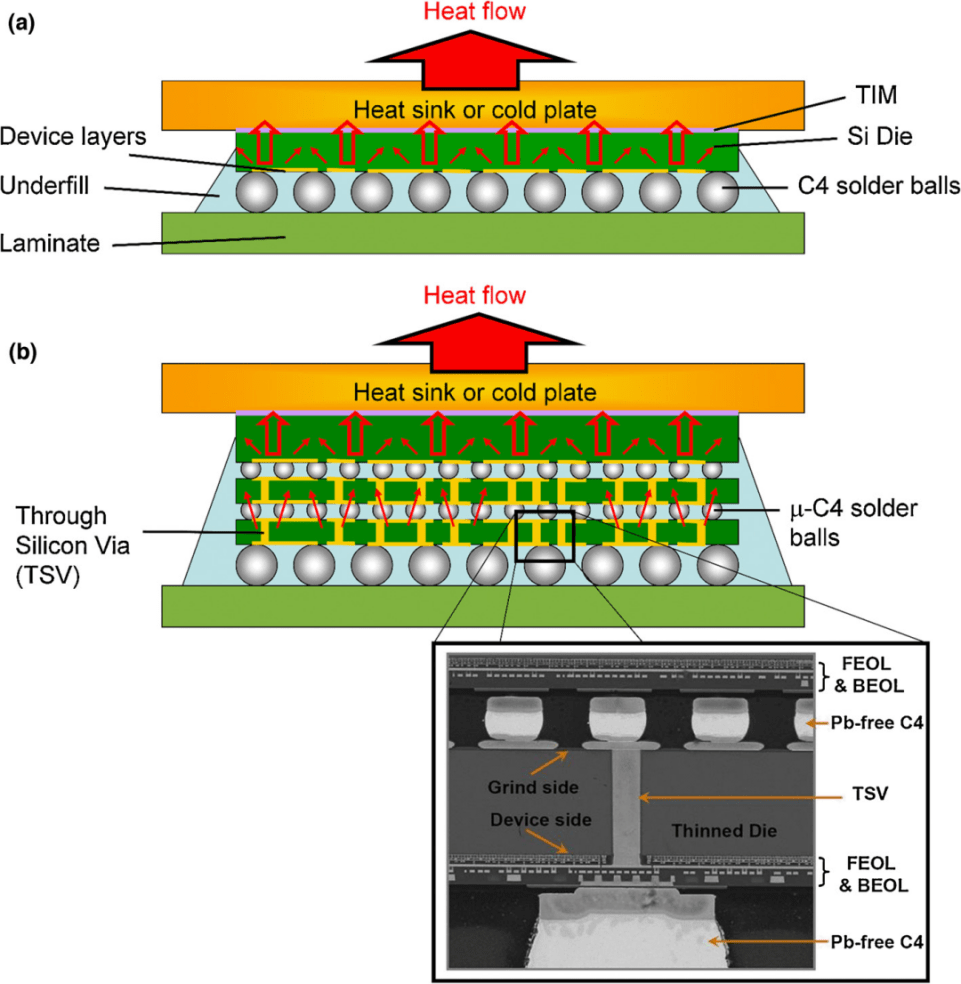

High power density not only affects individual chips, but also has a significant impact on the operational efficiency of data centers. With the popularization of nanoscale electronic devices, as well as the rise of three-dimensional chip architectures and flexible electronic technologies, thermal management issues have become particularly urgent. The increase in the number of interfaces and boundaries inside the chip may become an obstacle to heat flow, posing new challenges to the thermal management strategy of chip packaging.

The reliability of electronic products no longer depends solely on the average temperature of the chip, but on whether the hottest temperature can be effectively controlled. Therefore, selecting efficient heat dissipation materials, optimizing the design of heat sinks and cooling plates, and reasonably planning the cooling capacity at the system level are key to solving these problems. Diamond heat sink sheets have become a cutting-edge solution for solving this problem due to their extremely high thermal conductivity.

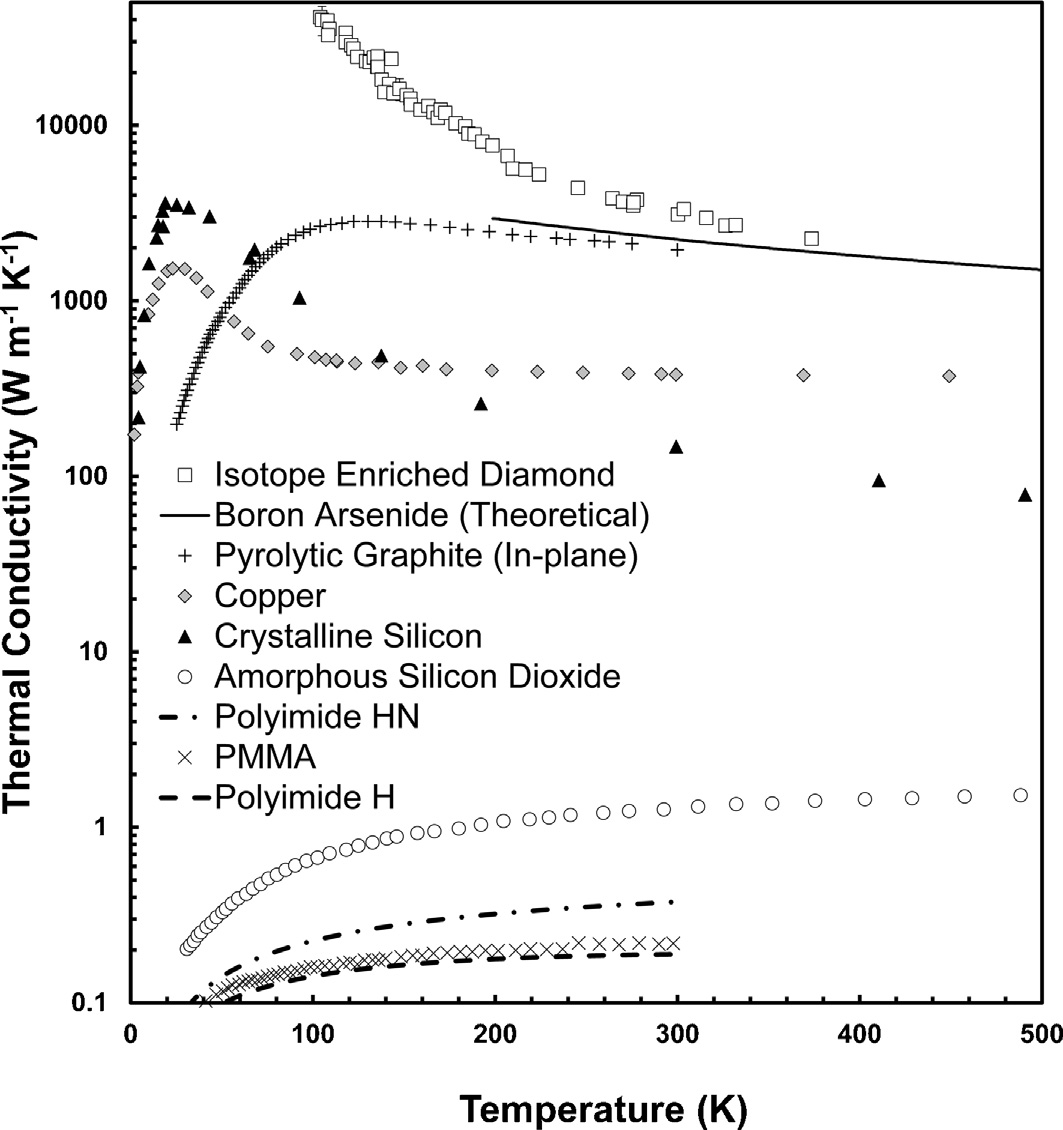

Temperature effect on thermal conductivity of bulk materials

CSMH focuses on the production and research of diamond materials, mastering world-class diamond production and processing capabilities, and providing customized services such as metalization, graphitization, and welding. The core products include diamond heat sinks,diamond wafers, diamond windows, diamond heterojunction integrated composite substrates, etc. The surface roughness of diamond wafer Ra<1nm, and the thermal conductivity of heat sinks can reach 1000-2000W/(m.K). Currently, they have been widely used in fields such as 5G communication, laser systems, radar, new energy vehicles, and solar photovoltaics.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message