At room temperature, the thermal conductivity of diamond is 5 times that of copper and 15 times that of Si, which has obvious advantages compared to other substances. The thermal conductivity requirement is between 1000-2000W/m.k. Diamond is the preferred and only optional heat sink material.

1. Single crystal diamond

There are two main ways in which single crystal diamond is used for heat dissipation. One method is to directly use it as a substitute for epitaxial substrates, in situ grow materials to prepare devices, and use the active region of the device to closely contact diamond, utilizing the ultra-high thermal conductivity of diamond to evenly distribute heat into the substrate. Another approach is to add microchannel structures to the single crystal diamond structure, utilizing fluids to carry out internal heat and achieve cooling.

Large area single crystal diamond substrates mainly provide epitaxial growth substrates for the development and industrialization of various electronic devices. High power diamond power electronic devices: They can replace existing Si, SiC and other power converters and switching power supplies, significantly reducing the size of converter components without the need for heat dissipation, achieving a significant improvement in conversion efficiency and a significant decrease in power consumption, and significantly improving reliability. The energy consumption of diamond electronic devices will be 1/3-1/5 of the current devices used.

Ultra high frequency high-power diamond electronic devices (microwave, millimeter wave radar): can be used in fire control weapon systems, radar, high-speed wireless communication, rockets, aerospace and other fields. It can replace the current use of traveling wave tubes, making weapon and communication systems more miniaturized and significantly improving reliability, significantly improving the data transmission rate of communication systems, and significantly reducing the weight, launch costs, and radiation resistance of satellites and other spacecraft.

Applied to integrated circuit chips: Developing the next generation of integrated circuit chips based on diamonds, completely solving the bottleneck problem of integrated circuit heat dissipation, making integrated circuits more large-scale and high-speed.

2. Polycrystalline diamond

At present, various technical forms of using diamond as a heat sink or substrate for power devices have been studied, including diamond bonding based on substrate transfer technology, low-temperature deposition based on diamond passivation layer, and device epitaxial growth on diamond. At present, room temperature bonding between polycrystalline diamond and Si, GaN, Ga2O3, etc. has been achieved through surface activated bonding (SAB) technology.

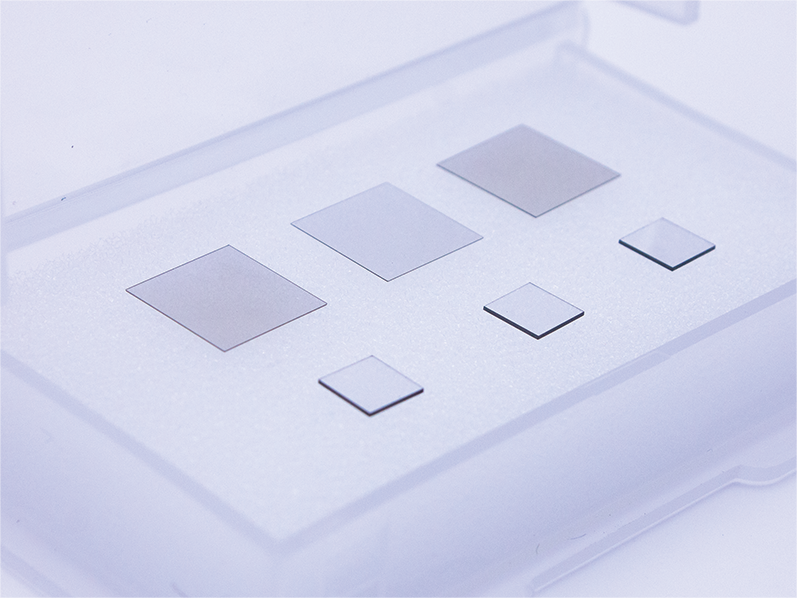

Polycrystalline diamond has high-performance advantages as a heat sink for high-power chips and electronic devices. In the future, with the increase of production and the decrease of cost, it is expected to be widely applied in the field of semiconductor heat sinks. At present, Chemo Semiconductor Manufacturing has achieved commercial mass production of 2-inch polycrystalline diamond and has the production capacity of 3-inch/4-inch diamond wafer.

3. Nano diamond materials

Nano diamond materials used for heat dissipation are generally used as passivation layers for high heat flux devices, which can be uniformly heated on the device surface, adding a thermal conductivity path to the device and improving its surface temperature uniformity performance. Hydrogen plasma has a reactive etching effect on GaN, which requires low-temperature conditions and hydrogen resistant design for direct diamond deposition in devices. On the surface of the hydrogen resistant protective layer, diamond needs to undergo uniform high-density nucleation and high directional arrangement to enhance the overall thermal conductivity of the diamond passivation layer.

The typical thermal management application scenarios of diamond include: diamond reinforced metal packaging materials (Diamond/Cu, Diamond/Al), heat sinks, diamond substrate GaN devices, etc. Diamond based heat sink is applied to the heat dissipation system of lasers, which can achieve efficient heat transfer and dissipation, reduce the working temperature of lasers, and improve the stability and lifespan of lasers.

The development demand for miniaturization and lightweight electronic devices is leading to changes in heat dissipation materials and solutions. Lightweight and high thermal conductivity have become the development goal of heat dissipation materials, and diamond has become one of the best choices.

CSMH is committed to the production and research of diamond materials, providing new ideas for heat dissipation of high-power devices, and promoting technological innovation in fields such as semiconductor lasers, high-power LEDs, new energy vehicles, radar, and aerospace. At present, mature products include diamond wafers, diamond heat sinks, diamond windows, diamond heterojunction integrated composite substrates, etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message