The increase in power density of electronic components and the resulting higher heat dissipation demand require new materials. Diamond has four to five times higher thermal conductivity than copper and is very suitable for cooling high power density electronic components, such as processors, semiconductor lasers, or electronic components used in electric vehicles. It is particularly important for cooling power electronics in power transportation, photovoltaics, or storage systems.

On March 1st, the Fraunhofer Association announced that its researchers have successfully developed an ultra-thin nanofilm made of synthetic diamond, which is thinner than human hair and can be directly integrated into electronic components, thereby reducing local heat load by up to 10 times. As a result, the energy efficiency, service life, and road performance of electric vehicles have been significantly improved. When used in charging infrastructure, diamond film helps to increase charging speed by five times.

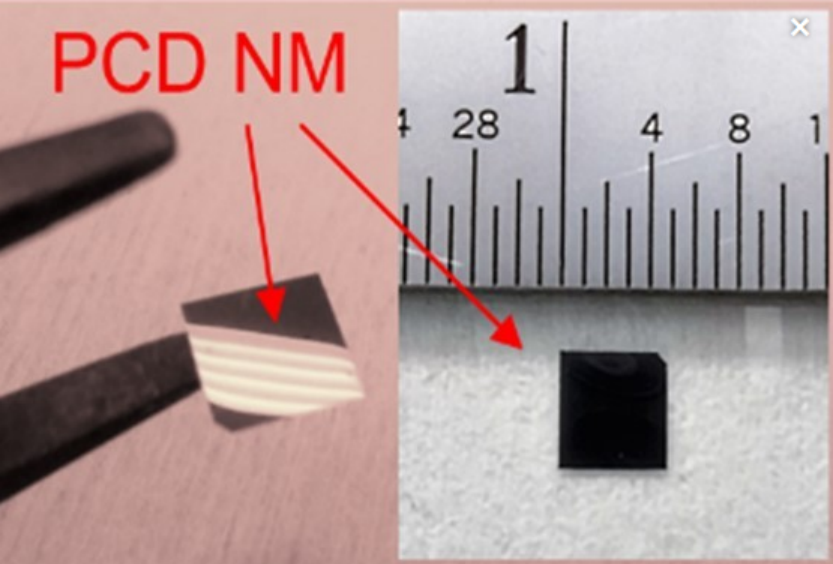

Photos of independent polycrystalline diamond nanofilms

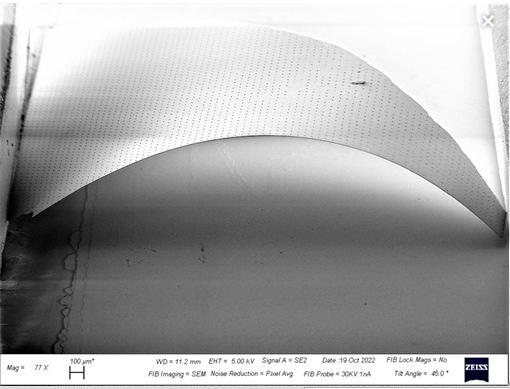

Generally speaking, applying a copper layer underneath a component can improve heat flow, but there is an oxide or nitride layer of electrical insulation between copper and the component with poor thermal conductivity. This type of nanofilm is very effective in transferring heat to copper, as diamond can be processed into a conductive path. Therefore, researchers hope to replace this intermediate layer with diamond nanofilm - flexible and independent thin films can be placed anywhere on the component or copper, or directly integrated into the cooling circuit.

SEM images of diamond nanofilms elastically bent under external mechanical impact

Diamond has excellent properties such as wide bandgap, high thermal conductivity, high breakdown field strength, high carrier mobility, high temperature resistance, acid and alkali resistance, corrosion resistance, and radiation resistance. It is currently one of the most promising semiconductor materials, and its classic application scenario is in the field of thermal management. By utilizing the high thermal conductivity of diamond, the heat dissipation effect of electronic components can be greatly improved.

Researchers grow polycrystalline diamond nanofilms on individual silicon wafers, then separate them, flip them over and etch off the diamond layer on the back, forming independent and smooth diamonds that can be heated at a low temperature of 80 degrees Celsius and then attached to the components. Heat treatment will automatically bond micrometer thick thin films onto electronic components, so that diamonds are no longer independent but integrated into the system.

CSMH focuses on the production and research of diamond materials, with world-class diamond production processes. It currently has products such as diamond heat sinks, diamonds wafers, diamond windows, and diamond heterojunction integrated composite substrates. Among them, the surface roughness of the diamond wafer Ra<1nm; The thermal conductivity of diamond heat sinks reaches 1000-2000W/m.k, which fully meets the production requirements as a heat dissipation material for high-power devices.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message