Pos:

Home KnowledgeTechnologyPerovskite Lasers with Effective Heat Dissipation Using Diamond heatsinkTraditional epitaxial-produced single-crystal semiconductors with substantial thermal conductivity κ and high charge carrier mobility m often display minor resistive heating under large current flow in commercially available electric injection lasers. Perovskites have small κ values while having substantial and balanced charge carrier mobilities.

Compared to GaAs, which have a thermal conductivity of 50 W m–1 K–1, MAPbI3 has a thermal conductivity of just 1–3 W m–1 K–1. As a result, heat generated due to energy loss via nonradiative pathways cannot be properly dispersed.

Due to the population inversion of any particular transition being diluted and other issues like deterioration and heat-induced flaws, this failure will raise the lasing threshold since carriers inhabit a wider energy range at a higher temperature. A distributed-feedback (DFB) perovskite laser’s lowest electric excitation threshold could reach 24 mA cm–2.

The external quantum efficiency would also be severely constrained under high current injection settings due to Joule heating in traditional perovskite light-emitting diode designs utilized for laser systems. Therefore, heat control is a barrier to the advancement of electrically powered perovskite lasers.

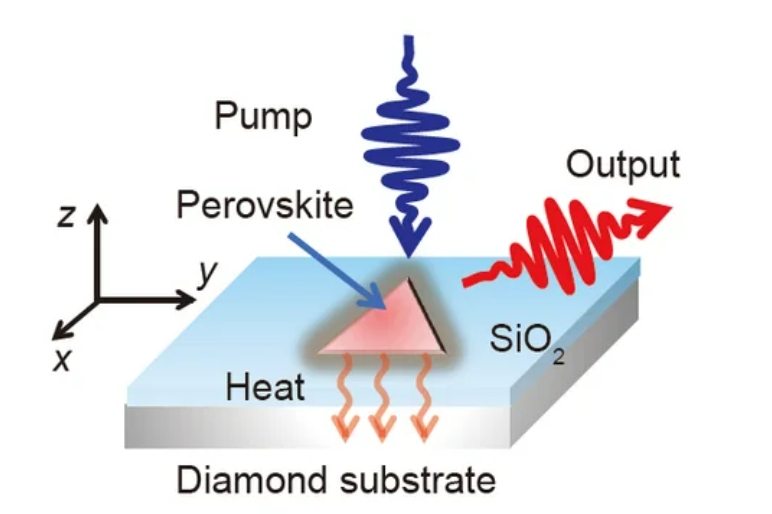

In this context, a team of researchers led by Professors Kaibo Zheng of Lund University and Guohui Li of the Taiyuan University of Technology demonstrated a perovskite nanoplatelet laser on a diamond substrate that can effectively dissipate heat produced during optical pumping. The laser being displayed has a Q factor of ~1961 and a lasing threshold of 52.19 μJ cm–2.

The addition of a thin SiO2 gap layer between nanoplatelets and the diamond substrate also results in a tight optical confinement. Electric field distributions inside the structures reveal that a broad SiO2 gap with a thickness of 200 nm evidently results in a reduced leakage field in the diamond substrate, while also suggesting improved mode confinement within the MAPbI3 nanoplatelet.

Temperature changes under optical pumping circumstances were used to measure the heat dissipation in perovskite nanoplatelet lasers on the diamond substrate.

Due to the inclusion of the diamond substrate, the laser has a low pump density-dependent temperature sensitivity (~0.56 ± 0.01 K cm–2 μJ−1). The sensitivity is between one and two orders of magnitude less than the values for perovskite nanowire lasers on glass substrates that have previously been reported.

The nanoplatelet laser can run at a high pump density owing to the diamond substrate’s high thermal conductivity. The study could serve as an inspiration for the creation of electrically powered perovskite lasers.

CSMH has been committed to the research and development and production of diamond materials. Now it has products such as diamond heat sink,diamond wafer, diamond window to provide customers with a comprehensive thermal management solution.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message