RF resistors able to operate above 8 GHz while handing >100 W are critical for successful operation of phased array radar and 5G wireless infrastructure. Fabrication of high power resistors able to operate above S-Band requires reducing its parasitic electrical characteristics to a minimum. In this work it is demonstrated that this cannot be achieved with traditional substrates (AlN and BeO), but would be achievable by using CVD diamond heat sink.

To date, beryllium oxide (BeO) and aluminum nitride (AlN) have been the preferred substrates for high power RF resistors. These ceramic materials have relatively high thermal conductivity and enable resistors to handle tens to hundreds of watts when operating at L and S bands (1 4 GHz). However, when operating from X band up to Ku band (8 30 GHz), the trade-off between maximizing the dissipated power and reducing resistor parasitic effects leads to a diminished ability of dissipating few watts when using BeO or AlN substrates. This limitation in management of power at higher frequency will become a bottleneck for extending high power applications above S-band. So CSMH proposed a solution for RF resistors capable of operating above 8 GHz while handing over 100 W by using CVD diamond as the resistor substrate.

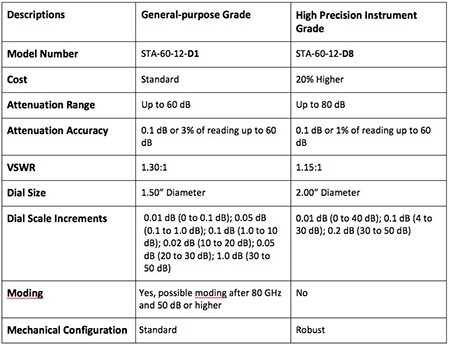

We summarized the values of the key parameters affecting performance for the different high thermal conductivity substrates used in RF resistors. It is evident that AlN, with the highest permittivity and the lowest thermal conductivity, will perform worse than BeO, and diamond having the best combination of low permittivity and highest thermal conductivity would excel as a high frequency resistive substrate.

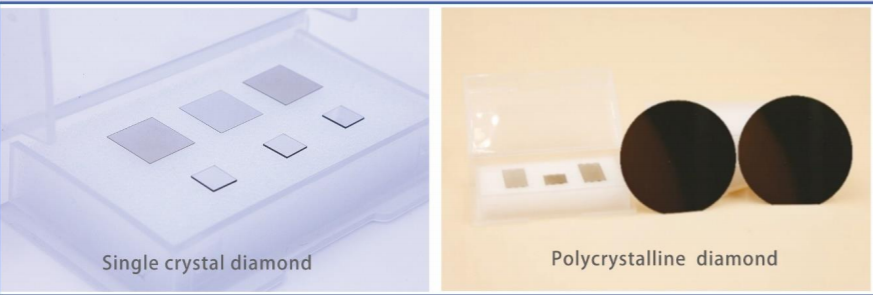

Temperature is also important when considering the thermal conductivity. At 125°C the thermal conductivity values for AlN and BeO are reduced by 30-40% from room temperature values. Thermal conductivity of the purest single crystal diamond may exceed AlN and BeO by a factor of ~10-15, which roughly would means that a resistor using diamond should be able to handle 10-15 times more power. When considering polycrystalline diamond as a resistive substrate with thermal conductivity ranging from 1000 W/mK to 2200 W/mK, a 4-8x improvement in performance over that of AlN and BeO could be realized.

Comparing the three resistive substrate options with the same thickness (1mm), it is clear that diamond with its lower permittivity yields the smaller capacitance per unit area value. Even a further reduction in capacitance values would be achieved through use of thinner diamond substrates enabling an improved cost/performance metric for the diamond solution.

A Wilkinson divider/combiner is a well-known and omnipresent circuit able to provide isolation between the output ports while maintaining a matched condition for all the ports. However, keeping this ideal behavior relies on the isolation resistor, which should satisfy the relation= 2Z0, with Z0 the impedance of the line (fixed at R=50 Ω). Hence any deviation of the resistor impedance (ideally 100 Ω) will result in a deviation from the ideal characteristics of the divider. CSMH found that resistors using good quality diamond are able to offer excellent performance at 10 GHz. For these particular frequency and power conditions the use of low grade diamond as a resistor substrate represents the lower limit to ensure a good performance for the chosen Wilkinson divider (|S11|≈-15 dB).

It has been demonstrated that by switching the substrate of high power RF resistors from AlN and BeO to CVD diamond it is possible to extend their operative frequency range well above X-band whilst handling powers above 100 W. This could offer a step change improvement towards minimizing distortion and complexity of high power electronics in 5G communications and military millimeter-wave devices operating in X-band and above.

CSMH is a wide bandgap semiconductor material company manufacturing with unique technology. CSMH have internationally leading technology to achieve high surface finish Ra<1nm and it could provide customized services on thickness, size and shape. We also offer diamond wafer, diamond window, diamond heterogeneous integration, etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message