Pos:

Home KnowledgeTechnologyDiamond wafer—the influence of the position on the heat dissipation ability of devicesDevice heat dissipation has always been a focus, and diamond has the highest thermal conductivity of all natural materials and can be used to dissipate the heat generated during device use. The position device of diamond has a great influence on heat dissipation. The simulated diamond block distance from the edge of the gate area changes from 0 to 2.0m, and the diamond thickness and the rate are 1.0μm and 10W/mm, respectively.

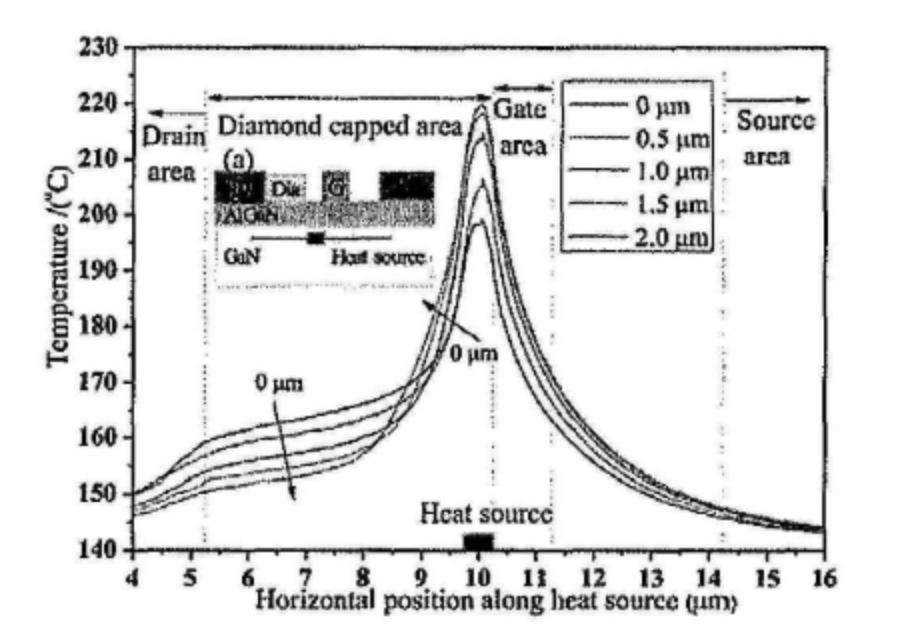

Figure shows the temperature distribution in the horizontal direction of the heat source at different distances between the diamond and the edge of the grid area. It can be seen from FIG. that the peak value of junction temperature greatly increases with the increase of distance, and this increase is almost linear in the early stage, but becomes smaller and smaller. The ratio of the peak junction temperature with diamond divided by the peak junction temperature without diamond is 0.897, 0.927, 0.967, 0.984 and 0.992, respectively, and the value is closer and closer to 1 as the distance increases. The results show that the heat dissipation can be realized when the diamond is close to the heat source.

At the same time, the temperature distribution along the horizontal position of the heat source shows that the temperature is mainly concentrated in the heat source region, and the peak temperature increases with the increase of distance. It is worth noting that the temperature distribution in the area in contact with the diamond tends to be uniform, while the temperature distribution trend in the area without diamond is almost unchanged. The temperature below naladite increases with distance. These results show that the closer the diamond is to the grid, the more effective the heat dissipation is. The results of 0.5μm diamond thickness agree well with the experimental data in the references, which proves the validity of the simulation model.

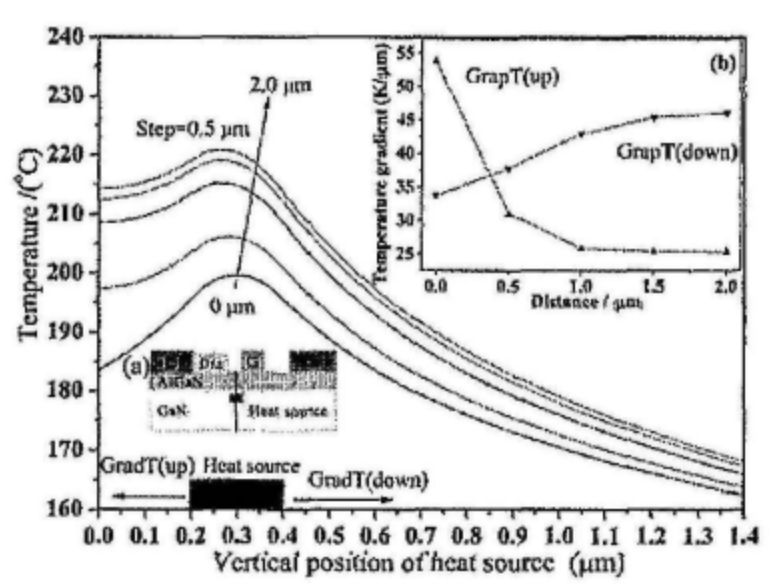

Figure shows the temperature distribution along the vertical direction of the heat source at different distances. As can be seen from the figure, the heat is mainly concentrated around the heat source, and the entire temperature curve decreases as the distance decreases. At the same time, as the distance decreases, the temperature drop slope above the heat source increases, and the closer the diamond is to the heat source, the greater the cooling effect. Due to the vertical heat transfer between the GaN buffer layer and the SiC base, the temperature of the region below the heat source decreases rapidly along the vertical position. It is worth noting that the temperature gradient (GradT) depends on the distance shown in Figure, when the distance is 0pm, GradT(up) is greater than GradT(down), so the heat transfer is mainly determined by GradT(up).

CSMH focuses on the research and production of diamond wafers. At present, it has diamond wafers, diamond heat sinks, GaN on diamond, AlN on diamond and other products. Among them, high-power semiconductor lasers packaged by diamond heat sinks have been used in optical communications. In the fields of laser diodes, power transistors, and electronic packaging materials, it can provide customers with diamond thermal management solutions.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message