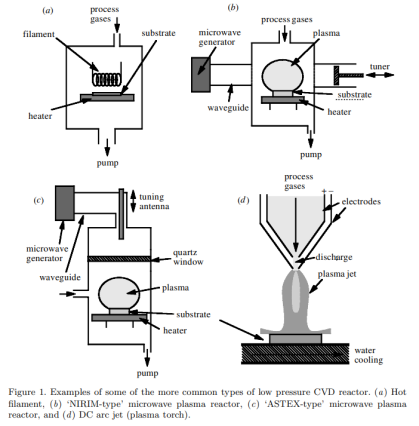

Chemical vapour deposition, as its name implies, involves a gas phase chemical reaction occurring above a solid surface, which causes deposition onto that surface. All CVD techniques for producing diamond films require a means of activating gas phase carbon-containing precursor molecules. This activation can involve thermal methods(e.g. a hot filament), electric discharge (e.g. DC, RF or microwave), or a combustion fame (such as an oxyacetylene torch). Figure 1 illustrates some of the more popular experimental methods. While each method differs in detail, they all share a number of features in common. For example, growth of diamond (rather than graphite) normally requires that the precursor gas (usually CH) is diluted in excess of hydrogen in a typical mixing ratio of 1%vol. CH. Also. the temperature of the substrate is usually greater than 700 °C to ensure the formation of diamond rather than amorphous carbon A detailed review of the various methods used for fabricating diamond can be found in Dischler & Wild (1998), but some of the more important will be mentioned here.

Hot filament CVD (HFCVD) (see figure 1a) uses a vacuum chamber continually pumped using a rotary pump, while process gases are metered in at carefully con.trolled rates (typically a total flow rate of a few hundred sccm). Throttle valves maintain the pressure in the chamber at typically 20-30 Torr, while a substrate heater is used to bring the substrate up to a temperature of 700-900°C. The substrate to be coated-e.g. a piece of Si or Mo sits on the heater, a few millimetres beneath a filament, which is electrically heated to temperatures in excess of 2200 °C. The filament is made from a metal that will be able to survive these conditions and not react significantly with the process gas. Metals such as tungsten and tantalum are most often used, although they do eventually react with the carbon-containing gases and carburize to form the metal carbide. This changes their resistivity and makes them brittle, reducing their lifetime and hence the maximum deposition time that can be performed in one run. The HFCVD method is relatively cheap and easy to operate and produces reasonable quality polycrystalline diamond films at a rate of ca.1-10 μm h-1, depending upon exact deposition conditions. However, it also suffers from a number of major disadvantages. The hot filament is particularly sensitive to oxidizing or corrosive gases, and this limits the variety of gas mixtures which can be employed. It is also very difficult to avoid contamination of the diamond film with filament material. For diamond to be used in mechanical applications, metallic impurities at the tens of ppm level are not a significant problem, but it becomes unacceptable for electronic applications. Furthermore, the predominantly thermal nature of the process means that there are very few gas phase ions present, and this reduces the effectiveness of biasing the substrate to improve growth rates or induce oriented growth.

Microwave plasma CVD (MWCVD) reactors use very similar conditions to HF reactors, and despite being significantly more expensive, are now among the most widely used techniques for diamond growth. In an MW reactor, microwave power is coupled into the chamber via a dielectric window (usually quartz) in order to create a discharge. The microwaves couple energy into gas phase electrons. Which in turn transfer their energy to the gas through collisions. This leads to heating and dissociation of the gas molecules, the formation of active species, and finally diamond deposition onto a substrate, which is immersed in the plasma. The two most common types of MWCVD reactor are the NIRIM-type (figure 1b) and the ASTEX-type reactor (figure 1c). In the NIRIM-type reactor (Kamo et al. 1983), a quartz discharge tube is inserted through the side of a fundamental mode rectangular wave guide appropriate for the propagation of2.45 GHz microwaves. The arrangement is such that the electric field maximum is centred in the middle of the discharge tube creating a stable plasma in that position. The exact position of the plasma can be altered by tuning using a sliding short in the wave guide. The substrate is introduced from the bottom of the discharge tube using a dielectric rod to prevent microwave leakage to the outside.

The other common type of microwave reactor (figure 1c) was designed in the late1980s (Bachmann et al. 1988), and was then commercialized by Applied Science and Technology, Inc. (ASTEX). In this reactor, microwaves are coupled into a water cooled metal cavity through a quartz window, using an antenna which converts the TEro microwave mode in the wave guide to the TMo mode in the cavity. The inner chamber diameter is chosen so that only one microwave radial mode can be sustained in the cavity at 2.45 GHz. Substrates as large as 10 cm in diameter can be coated by positioning them on a heated stage beneath the plasma ball which forms immediately above it. Microwave powers of up to 5 kW can be used in such systems giving growth rates well in excess of 10 μm h-1.

As well as high powers and hence higher growth rates, other advantages of microwave systems over other types of reactors are that they can use a wide variety of gas mixtures, including mixtures with high oxygen content, or ones containing chlorinated or fluorinated gases. The fact that no filament is involved makes MWCVD systems inherently cleaner than HFCVD systems, and so they have become the system of choice for electronic applications. Furthermore, the presence of a significant number of ions within the discharge allows the possibility of deliberately altering the deposition conditions by biasing the substrate. The most important use for this has been in so-called bias-enhanced nucleation (BEN). whereby a negative potential typically 100-200 V) is applied to the substrate heater for the first few minutes of the deposition process. This is believed to accelerate carbon-containing ions onto the substrate, causing them to sub-plant beneath the surface and create a carbon-rich layer in the topmost few layers of the substrate. This has two important effects: (i)the initial nucleation rate is greatly increased, and (ii) the resulting diamond film is registered with the underlying substrate lattice to a much greater extent, allowing films with a preferred orientation to be grown.

Plasma jet, arc jet or plasma torch methods are a promising alternative to the more conventional low-pressure HF and MW systems, and were introduced in the mid- to late-1980s. ln a plasma jet, gas at relatively high flow rates (litres per minute compared with cm' per minute used for HF and MWCVD) passes through a high power electrical discharge and forms a jet of ionized particles, atoms and radicals which then expand into a secondary chamber to strike a substrate at high velocity Plasma jets are usually distinguished by the pressure within the secondary chamber which can be ca.100 Torr to 1 atm. and by the methods in which the electrical discharge is sustained. The most commonly used plasma jet is the DC arc jet (see figure 1d). which uses a direct current to drive high, relatively stable currents through the ionized flowing process gases. Other technologies which are emerging include electrode less discharges, such as the RF inductively coupled and microwave plasma jet sources. The main feature of all these plasma jet techniques is the high growth rates that can be achieved (typically greater than 100 μm h-1). Indeed, an arc jet has produced the highest diamond growth rates yet reported of greater than 900 μm h-1 (Ohtake & Yoshikawa 1990), which is nearly three orders of magnitude higher than most HF or MWCVD systems. However, the main drawback of such high power, high rate systems is that the deposition area is limited to the small area struck by the jet(usually ca. 1 cm2). Substrate cooling is a major problem, since maintaining uniform substrate temperatures in such a rapidly varying high power system is difficult. Even with excellent cooling, the thermal shock experienced by the substrate when the jet is both ignited and extinguished prevents the use of many substrate materials Silicon often shatters, so the material of choice is usually Mo. But even with Mo the rapid contraction of the cooling substrate that occurs when the jet is turned off often causes the diamond coating to delaminate from the substrate and form are e-standing diamond plate. For the purposes of creating an adherent coating, this is obviously a problem, but on the other hand, it does allow a simple method for making free-standing diamond plates.

A variant on the plasma jet is the simple oxyacetylene welding torch, also called the combustion fame method (Hanssen et al. 1988: Morrison & Glass 1994). Since this system is very cheap, and can be operated in air at atmospheric pressure without the need for complex vacuum equipment, it proved a popular technique for growing diamond in the early- to mid-1980s. In these systems, the torch is operated in a regime where the acetylene flow is slightly higher than the oxygen flow, and this creates a region within the flame (called the acetylene feather) which is high in carbon.containing radical species. lf a substrate is placed within this region of the flame, a diamond film will grow at rates of up to 200 μm h-1. However, the main drawbacks of the combustion flame method are similar to those for the plasma jet. The radial non-uniformity of the deposited material limits the area which can be coated, and cooling the substrate in a reliable and uniform manner is also problematic, leading to the presence of a significant amount of non-diamond carbon. Because of these limitations, welding torches are gradually being replaced by flat-fame burners (Clumac & Goodwin 1993), which are more appropriate for larger-area deposition.

Some other deposition methods have been employed to grow diamond thin films with varying degrees of success, including laser-assisted CVD, pulsed laser deposition and hydrothermal growth, and these are detailed in Dischler & Wild (1998). However it still remains to be seen whether any of these will be able to compete with MWCVD as the method of choice for high growth rate, high quality, and large area deposition.

CSMH focuses on the research and production of diamond wafers, and currently has diamond wafer, diamond heat sink , GaN on diamond ,AIN on diamond and other products, providing diamond thermal management solutions for our customers.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message