Pos:

Home KnowledgeTechnologyDielectric properties of single crystalline diamond wafers with large area at microwave wavelengthsControlled thermonuclear fusion is considered one of the most promising and attractive alternative energy sources due to its reduced CO2 emission. At present, the international project to build a facility to verify its feasibility, the International Thermonuclear Experimental Reactor (ITER), is ongoing. For plasma confinement extended in time, additional heating and current drive systems are required. Injection of high frequency (170 GHz) electromagnetic waves mitigates MHD (Magneto-Hydrodynamic) instabilities which occur in the plasma. For injection of millimeter waves with high energy, a microwave transparent window with high thermal conductivity and low microwave losses is mandatory. These windows should also act as a barrier for the tritium present inside the reactor's vacuum vessel, to avoid its dispersion in the facility environment. In principle, material properties of diamond can satisfy these requirements. Diamond has several characteristics which are superior to those of other relevant materials (like, for example, sapphire or fused silica), such as mechanical hardness, optical transmissivity, and high electrical breakdown threshold .

However, commercially available sizes of single crystal diamonds are much smaller than those of polycrystalline ones and other semiconductor materials. In this manuscript, we report the first measurement of dielectric properties of such tiled-clones of SCD. While its size is still smaller than the practical size, it is considered to be meaningful if we could provide some fundamental information about it for further development and the fabrication of wafers with larger size.

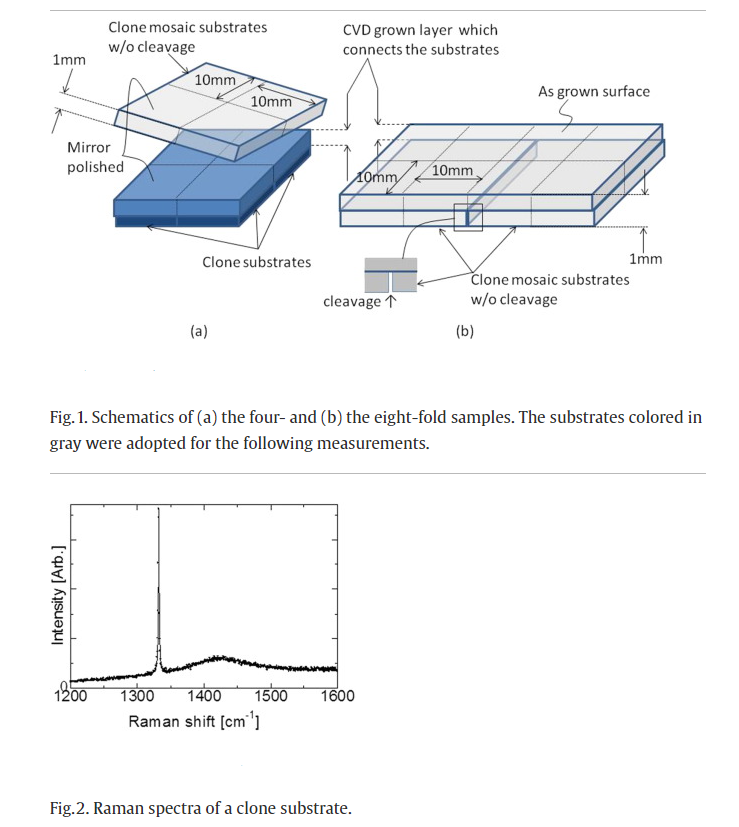

As reported in the preceding works, a single crystal diamond was grown by using microwave plasma chemical vapor deposition (MPCVD). 5–10 kW of microwave power was introduced into the vacuum chamber which was filled with the source gas mixture at 10–20 kPa of pressure. The source gas mixture was 90% of hydrogen and 5% of methane, with approximately 100 ppm of nitrogen. The grown diamond layers are divided from the seed wafer by using a lift-off process with high-speed ion beam injection. As described in the previous reports, we applied such lift-off process several times on identical seed crystals to have freestanding wafers all with similar characteristics. We shall call such wafers as “clone wafers”. Then, we grew SCD layers on these clone wafers. This overgrown SCD layer connects clone wafers with each other, as the so-called “tiled-clones”. Finally, we had the free standing wafers of the tiled-clones. The thickness of the tiled-clones, which were used for the measurements were adjusted around 1 mm. All samples consist of 4 and 8 clones with an area of 1 cm2 each. In the following we shall call them four- and eight-fold samples, respectively. Fig. 1(a) and (b) shows the four- and eight-fold samples, where the substrates colored in gray were adopted for the dielectric measurements. In the case of the four-fold sample, the substrate was polished and the boundary is almost invisible. On the other hand, in the case of the eight-fold sample, the boundary is visible because the surface opposite to the as-grown side was not polished and not fully filled by the CVD layers as shown in Fig. 1(b). The main reason of this is the high effort necessary to polish the substrates even at this size, i.e. 40 mm edge length and this was left for future work. Fig. 2 shows the Raman spectrum, which was measured at a boundary of a mosaic substrate by using a HORIBA Jobin Yvon T64000 system with a Nd:YAG laser source operating in second harmonic at a wavelength of 532 nm. The full-width-half-maximum (FWHM) of the peak at 1332 cm−1 originated from the diamond structure is approximately 2 cm−1 even on the boundary, which is similar to that of commercially available CVD diamond samples. The broad peak around 1420 cm−1 is associated to the fluorescence from a nitrogen-vacancy center. As it can be seen in the figure the sp2 graphite like peak at 1583 cm−1 is missing. Breaking of the mosaics sometimes happens owing to some stresses during the growth caused by, for example, a difference in the impurity concentrations. In such a case, cracking generates regardless of the boundaries. Therefore, we consider that the effect of the boundary on the toughness would be small.

The measurements performed included loss tangent characterization in three different Fabry–Perot resonators: hemispherical (variable frequency source, 90–100 GHz, Δ(tanδ) = 10− 5), double spherical resonator (170 and 145 GHz, Δ(tanδ) = 10− 6) and hemispherical XY mapping (145 GHz, Δ(tanδ) = 10− 5). The beam profile used in the tests is the basic Gaussian TEM00. The measurement technique used in the resonator consists in a first set of measurements with empty resonator to record the Q-factors of the various resonator modes followed by the measurements with the samples inserted. A comparison between the resonance frequency and cavity quality factor of the empty resonator and of the resonator with the sample is then carried on. The final values of the loss tangent are obtained from the calculation of the inverse Q-factors. The relative permittivity εr is extracted by solving the resonator equation iteratively]. The double spherical resonator is also equipped with a micro-positioning system on which the sample is mounted. In this way, it is possible to move the sample to alternate between wave maxima at the surface and inside the sample itself. This allows us to distinguish between bulk and surface losses. The surface contribution to the global tanδ varies from a minimum when the node of the wave corresponds to the face of the sample (resonant condition) to a maximum when this correspondence involves the antinode (antiresonant condition).

The measurement of dielectric properties of large size SCD tiled-clone wafers was conducted for the first time. Even though it is still technically hard to produce 4 inch size wafers of such SCD tiled-clones, we obtained results that are promising. Results indicate that the sample where both sides are polished has dielectric tanδ as low as that of the polycrystalline diamond with high quality. On the other hand, results show importance of surface treatment, especially on the boundaries between the single tiles even if there are no sp2 graphite-like components in the wafers. To obtain practical size and quality of the SCD wafers for the use in windows, it is required to polish such large size wafers without cracking within and to achieve this within a practical processing time. This is left for future work.

CSMH focuses on the research and production of diamond wafers, and currently has diamond wafer, diamond heat sink , GaN on diamond ,AIN on diamond and other products, providing diamond thermal management solutions for our customers.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message