Pos:

Home KnowledgeTechnologyInnovation in Electronic Packaging Materials: Technological Breakthroughs of Diamond Composite MaterialsWith the Rapid Development of High-Performance Electronic Devices with High Power Density, Efficient Heat Dissipation Has Become an Increasingly Critical Issue.Diamond composite materials have attracted widespread attention and are regarded as the most competitive candidate materials for the next generation of electronic packaging materials. The crystal structure of diamond is a very stable covalent-bonded cubic crystal system; this uniform and highly ordered crystal structure endows diamond with high hardness and stability. The thermal conductivity of single-crystal diamond can reach 2000 W/(m·K), far exceeding that of traditional thermally conductive materials, and it can maintain excellent thermal conductivity even in high-temperature environments. However, due to the high cost and brittleness of diamond, its application as a single material is somewhat limited. Therefore, combining diamond with other materials to obtain more economical, practical, and malleable materials has become one of the current research hotspots.

Performance Advantages

This material system cleverly combines two materials with extreme properties:

Thickness : 0.3-2mm

Size:Maximum 100 x 100 mm2, customizable

Thermal Conductivity:TC600 - 1000 W/(m.K),Customizable

CTE:7 - 9 x 10-6/K @room temperature

Thermal Stability:1000 thermal shocks from - 65°C to 150°Cwith less than a 5% performance decrease

Special Process:Can be used in a three-layer structure,thick copper-diamond copper-thick copper

Applications in the Field of Electronic Packaging

1. Packaging Substrates

As microelectronic technology moves toward high-density assembly and miniaturization, the performance requirements for packaging substrates—such as thermal conductivity and CTE—are becoming increasingly stringent. With its high thermal conductivity, low CTE, and good stability, diamond has become a focus of attention for the next generation of packaging substrate materials. Diamond/metal matrix composites, prepared by combining diamond particles with high-thermal-conductivity metal matrices (e.g., Ag, Cu, Al), have initially demonstrated great potential in the field of electronic packaging.

2. Chip Heat Dissipation Packaging Structures

Diamond composite materials can be used to manufacture heat dissipation components in chip heat dissipation packaging structures, such as heat dissipation fins and heat dissipation columns. Compared with traditional heat dissipation materials, they can more effectively dissipate the heat generated by chips, improving the operational stability and reliability of the chips. At the same time, they can reduce the size of the packaging structure, meeting the miniaturization needs of electronic devices.

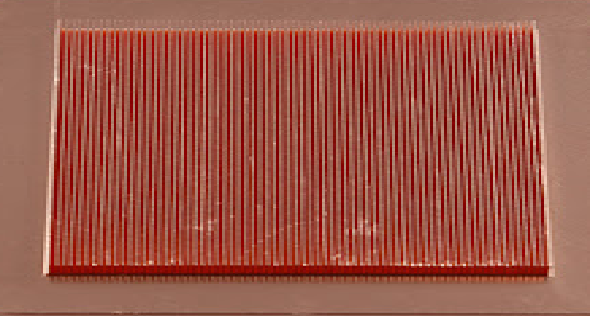

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.Among these, diamond-copper composite materials have been applied in fields such as AI chips, servers, optical communication, and lasers.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message