Pos:

Home KnowledgeTechnologyDiamond wafer, an excellent heat sink material for high-power semiconductor laser packagingSemiconductor laser, also known as laser diode, is a laser that uses semiconductor materials as working materials. It has the advantages of small size, long lifespan, high electro-optic conversion efficiency, and good stability, and is widely used in industrial processing, laser communication, laser lighting, laser gyroscopes, laser marking, laser medical treatment, scientific research, ranging, and radar. Many applications require semiconductor lasers to have high output power, high reliability, and long service life.

In the production process of semiconductor lasers, it is necessary to package the laser chip. Currently, the laser chip is packaged into a component laser chip single tube COS (Chip On Submount). The laser chip is soldered to the transition heat sink, and then soldered to the heat sink to make module applications. The packaging technology of laser chip single tube welding onto transition heat sink requires good heat dissipation conditions to maintain the long-term stability of the laser. The matching degree between the thermal expansion coefficient of the heat sink and the chip (thermal expansion coefficient of 6.4 × 10-6/K) directly affects the stress release between materials, which puts certain requirements on the heat dissipation ability of the transition heat sink and the thermal stress release ability of the heat sink material.

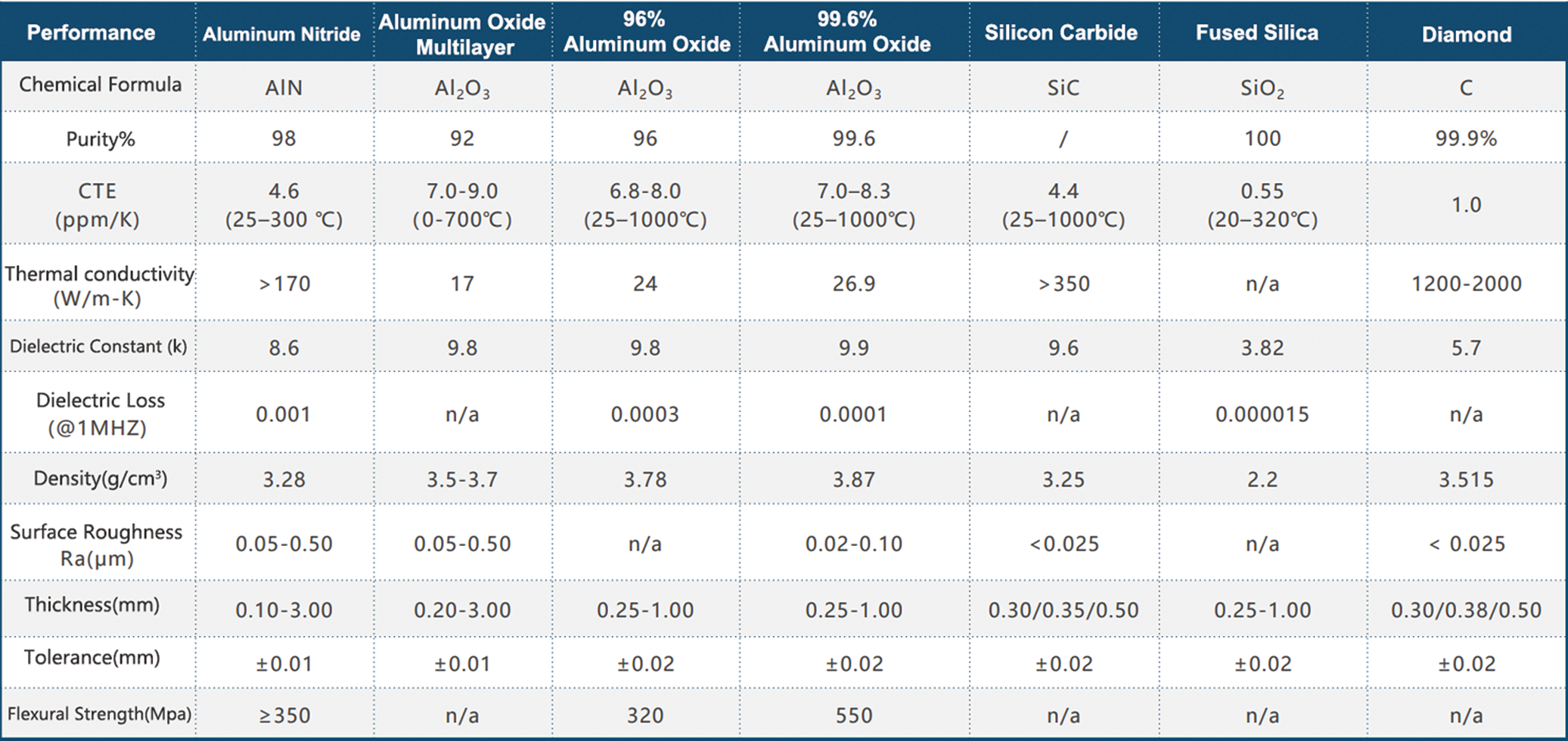

Common heat sink materials in the market include aluminum nitride (AlN), tungsten copper (WCu), silicon carbide (SiC), beryllium oxide (BeO), diamond, graphene, etc. They have some unique characteristics and are applied to different fields according to actual needs.

The thermal conductivity of SiC ceramics is high, and the higher the purity of SiC crystals, the greater the thermal conductivity; The biggest drawback of SiC is its high dielectric constant and low dielectric strength, which limits its high-frequency applications and is only suitable for low-density packaging. AlN material has excellent dielectric properties and stable chemical properties, especially its thermal expansion coefficient that matches silicon, making it a promising semiconductor packaging substrate material. However, the current highest thermal conductivity is only 260W/(m · K). With the increasing demand for heat dissipation in semiconductor packaging, AlN material also faces certain development bottlenecks.

Diamond has extremely high thermal conductivity and is an ideal heat dissipation material. Single crystal diamond has a thermal conductivity of over 2000W/m.k, while polycrystalline diamond has a thermal conductivity of 1000-2000W/m.k. At the same time, the thermal expansion coefficient of diamond is extremely low.

Comparison of Characteristics of Several Different Heat Sinking Materials

CSMH is committed to the research of heat sink materials, mastering professional and leading thermal management products and solutions, and can provide COS packaging, TO packaging, etc. CSMH has a mature product system, including diamond heat sinks, diamond optical windows, diamond wafers, diamond heterojunction integrated composite substrates, etc. The products have been applied in many fields such as high-power lasers, aerospace, radar, and new energy vehicles.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message