All semiconductor devices have a certain failure rate, and under high reliability requirements, it is necessary to test the completed products to ensure product quality.Chip aging testing is a very effective method, especially for high-speed and high power consuming devices such as lasers.

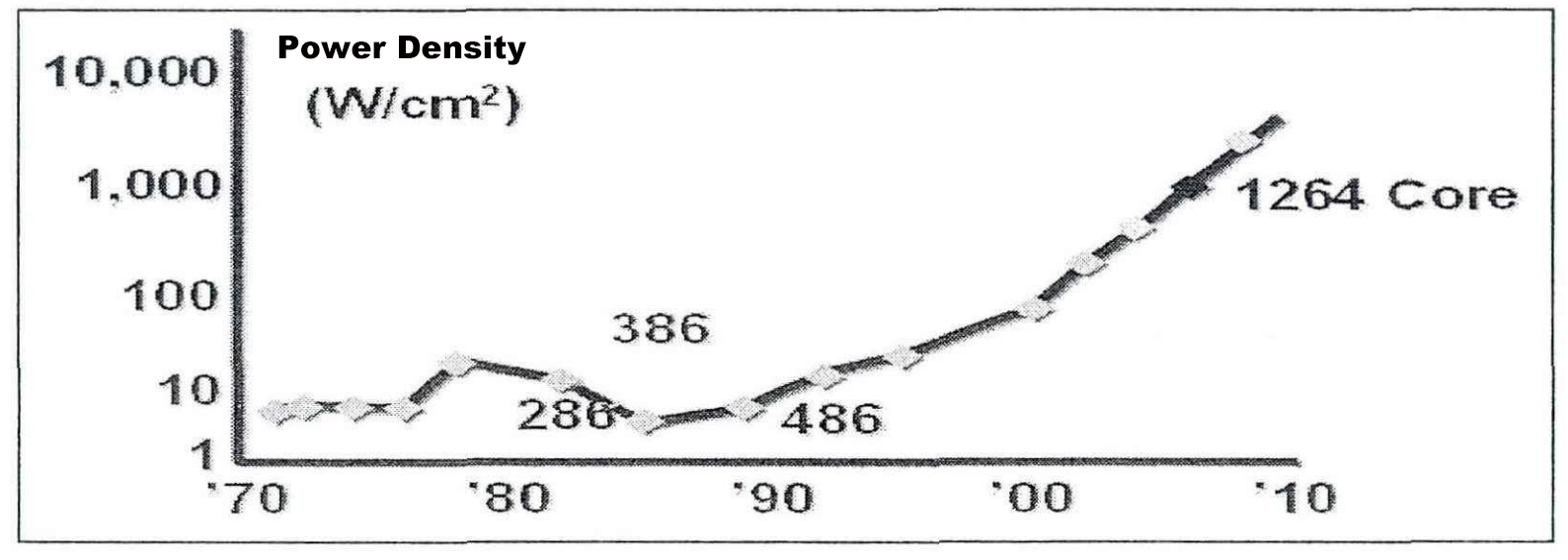

In the 1970s, the maximum power per square centimeter of integrated electronic chips remained at around 10W, increased to 20-30W in the 1980s, and rose to the level of 102 W in the 1990s. For the testing phase, especially the aging testing phase, the increase in chip operating power requires an increase in testing power. Chip aging testing will release more heat. If the heat dissipation problem is not solved, it will directly affect device performance, leading to a decrease in lifespan and reliability, and even damage to the chip.

Traditional semiconductor aging equipment, which uses copper sockets and chips in direct contact, usually has some problems:On the one hand, the heat dissipation effect is not good, and the heat of the chip increases during the testing process, resulting in the chip being scrapped;On the other hand, the copper seat is worn and has a short service life.

Diamond materials have ultra-high thermal conductivity. Combining diamond with copper seats can significantly improve the speed of heat transfer, thereby protecting the chip from aging tests. In addition, diamond has ultra strong hardness. When using diamond as a transitional heat sink in aging testing of copper seats, the wear resistance of diamond can provide the lifespan of the copper seat for testing.

CSMH focuses on the production and research of diamond materials, mastering the internationally leading diamond production technology, and can provide corresponding solutions according to different customer needs. Among them, the surface roughness of diamond wafers is Ra<1nm, and the thermal conductivity of diamond heat sinks reaches 1000-2000W/(M.K). The products include diamond wafers, diamond heat sinks, diamond window chips, diamond heterojunction integrated composite substrates, etc, It can meet the cooling needs of many high-power devices. Welcome to consult.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message