Pos:

Home KnowledgeTechnologyEfficient thermal management materials , diamond wafer will surely occupy a place!Diamond is one of the most important materials for third-generation semiconductors, also known as the "ultimate semiconductor", with physical, chemical, electronic, optical, thermal and mechanical properties that are unmatched by other existing semiconductor materials. Wide band gap, high thermal conductivity, high breakdown field strength, high carrier mobility, high temperature resistance, acid and alkali resistance, corrosion resistance, radiation resistance, these advantages will make it in high frequency, high power, high temperature electronic devices, nuclear radiation detectors, optoelectronic devices, microelectromechanical systems (MEMS) and other fields to show great application potential, while traditional semiconductor materials such as silicon, gallium arsenide and other because of their own characteristics of the limitations in these areas will encounter bottlenecks. It can be said that diamond is currently one of the most promising semiconductor materials, and its classic application scenarios include diamond thermal management materials.

Why is diamond suitable as a thermal management material? This is largely determined by its structure. Diamond is composed of carbon atoms, belonging to the cubic crystal system, its crystal structure is: in a face-centered cubic unit cell there are four carbon atoms, located at a quarter of the four diagonal lines of space, each carbon atom through sp3 hybridization and the other four carbon atoms form a covalent bond, constituting a tetrahedron. Diamond's special crystal structure and strong carbon-carbon bonding make it have many outstanding properties. In addition, diamond transmits heat through lattice vibration, and the quantum energy of carbon atoms to generate vibration is larger, that is, the vibration frequency is very high, so the thermal conductivity is very high.

Due to its low coefficient of thermal expansion and high insulation, diamond materials can be applied to excellent heat sinks for power electronic devices and solid microwave power devices. The working temperature and working power of the device have been greatly improved. In addition, CVD diamond is lower in cost than single crystal diamond, and has high thermal conductivity and low surface roughness, which is convenient for introduction into the semiconductor power device structure, significantly improving the heat dissipation capacity of the device, and has a broader application field.

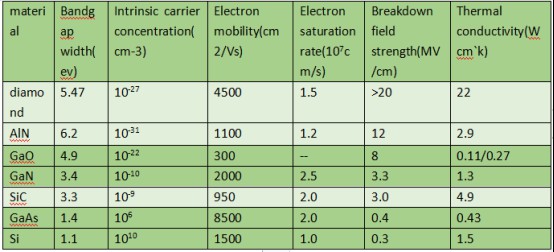

Figure 1, Diamond compared to other heat dissipation materials

The thermal conductivity of natural diamond at room temperature (25 °C) can reach 22W/(cm·K), and as a comparison, the thermal conductivity of metallic copper is about 4W/(cm·K), while the thermal conductivity of the traditional semiconductor material silicon is less than 2W/(cm·K). Taking gallium nitride (GaN) power devices as an example, the use of high thermal conductivity diamond as a heat sink for high-frequency, high-power gallium nitride (GaN) devices can reduce the self-heating effect of gallium nitride (GaN) high-power devices, and is expected to solve the problem of rapid decline in power density with the increase of total power and frequency. For high-power RF and optoelectronic devices, CVD diamond heat sinks can operate at higher power levels without pushing up the operating junction temperature, resulting in longer life and improved reliability. So in contrast, diamond is the most suitable material for heat dissipation.

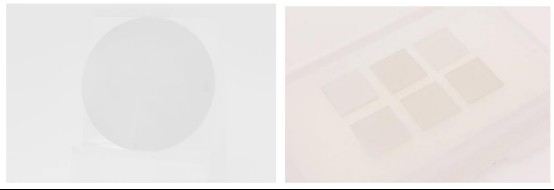

CSMH focuses on the research and development and production of diamond, with MPCVD equipment design capabilities, the first in China to master the core process of MPCVD preparation of high-quality diamond and achieve mass production, and the original based on plasma-assisted polishing of diamond atomic-level surface efficient precision processing method, diamond wafer Ra < 1nm, diamond hot deposit thermal conductivity of 1000-2000W/m.k, and GaN on diamond, Diamond on GaN, diamond-based aluminum nitride and other products, providing you with the most complete diamond thermal management solutions. High-power semiconductor lasers using diamond heat sinks have been used in optical communications, and have also been used in RF power amplifiers, laser diodes, power transistors, electronic packaging materials and other fields.

Figure 2 High-quality wafer-grade diamonds produced by CSMH

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message