During the operation of semiconductor lasers, a large amount of heat is generated. If the heat cannot be dissipated in time, it will affect the various performance of the laser, such as wavelength redshift, increased threshold current, decreased slope efficiency, and reduced power. In severe cases, it may even lead to laser failure. Heat dissipation and sealing technology is the key to ensuring the stable operation of the laser.

Based on the heat sink conduction cooling method, not only can the heat dissipation capacity of the laser be effectively improved, but also the working reliability of the laser can be effectively improved. Heat sink cooling and heat dissipation packaging is generally divided into two parts: zero level heat sink and heat sink. During chip operation, the heat generated in the active area is first transmitted outward through the zero level heat sink, and then the heat sink serves as the heat dissipation terminal to transfer all the heat to the cooling medium. Heat sink generally refers to oxygen free copper or other high conductivity materials. Zero level heat sink, also known as transition heat sink, is directly connected to the laser chip and heat sink. The thermal expansion coefficient, thermal conductivity, and other characteristic parameters of the transition heat sink material play a crucial role in the heat dissipation capacity of the laser.

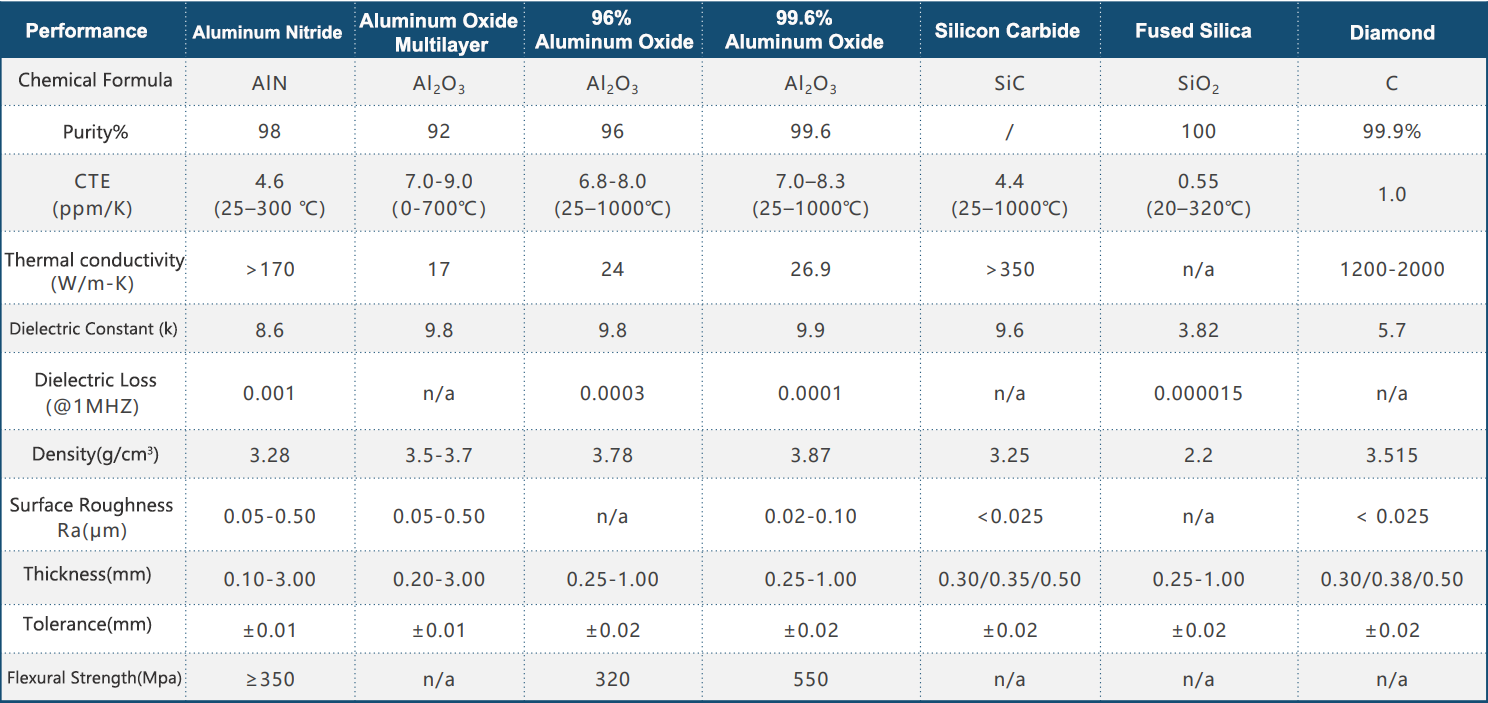

Common heat sink materials in the market include aluminum nitride (AlN), tungsten copper (WCu), silicon carbide (SiC), beryllium oxide (BeO), diamond, graphene, etc. They have some unique characteristics and are applied to different fields according to actual needs.

Diamond has extremely high thermal conductivity and is an ideal heat dissipation material. Single crystal diamond has a thermal conductivity of over 2000W/m.k, while polycrystalline diamond has a thermal conductivity of 1000-2000W/m.k. At the same time, the thermal expansion coefficient of diamond is extremely low.

Comparison of Characteristics of Several Different Materials

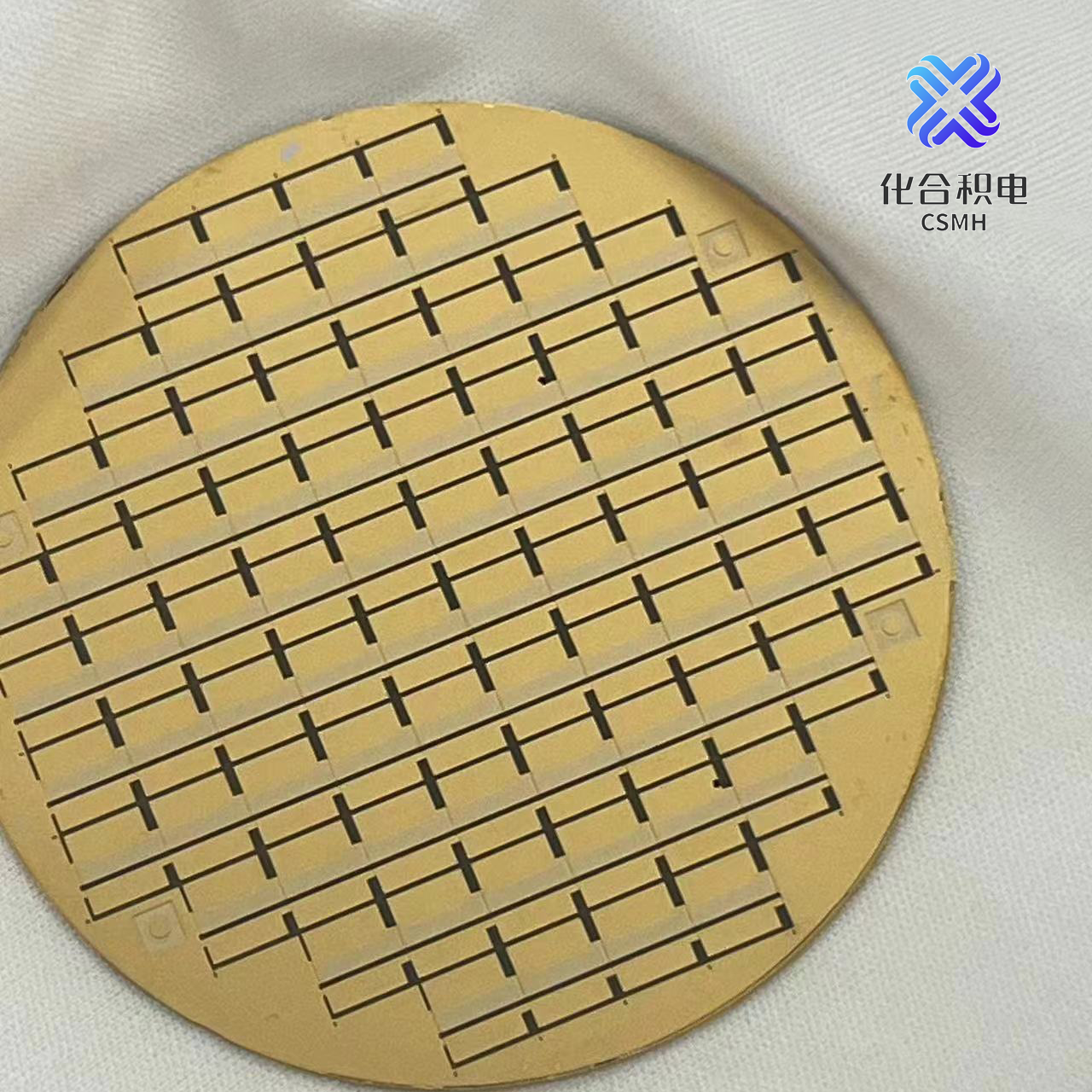

CSMH is committed to the research of heat sink materials, mastering professional and leading thermal management products and solutions, and can provide COS packaging, TO packaging, etc. CSMH has a mature product system, including diamond heat sinks, diamond windows, diamond wafers, diamond heterointegrated composite substrates, etc. The products have been applied in many fields such as high-power lasers, aerospace, radar, and new energy vehicles.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message